Injection moulding brings a slick contemporary look to food and other products with the added advantage of a secure pack seal. With flexible design options, injection moulding can be used for all kinds of caps and lids, increasing usability of the pack and the safety of a guaranteed fit.

Vexcel Pack’s extensive knowledge of process and materials ensures the design and production of a pack reduces the risk of leakage and maximises visual appeal.

INJECTION MOULDING

CAP SIZE : (Diameter Min 76.2 mm – Max 95 mm.)

• Guaranteed fit to Vexcel Pack rigid containers

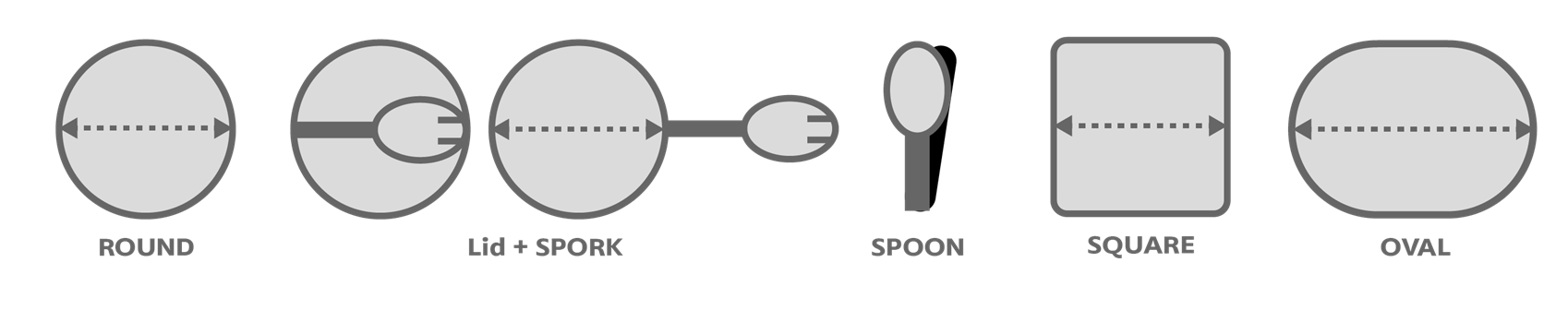

• Patented auslid lids and utensil products

• Leak-proof, tamper-proof and easy-seal design

• Pack design and tool design

• Integrated utensil in lids

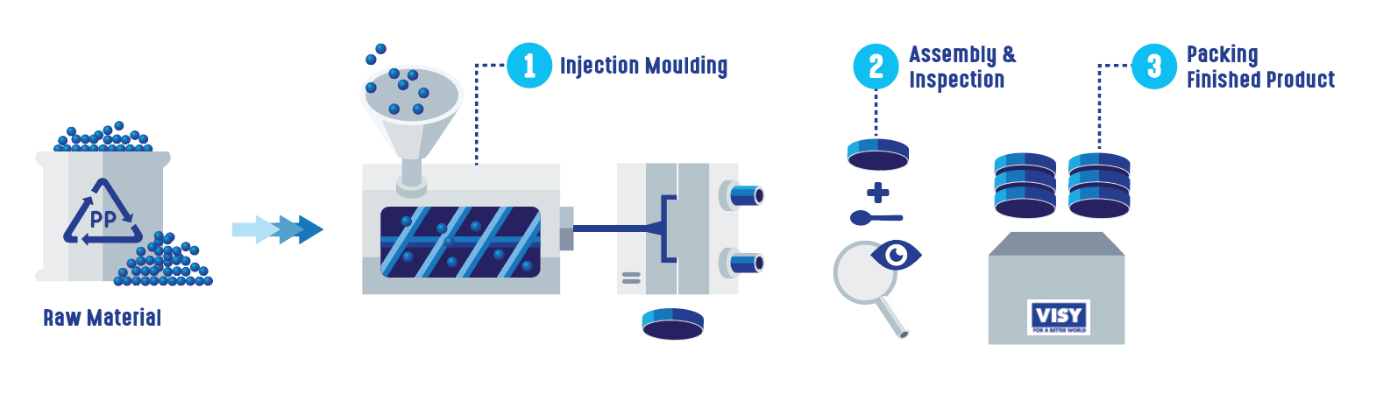

INJECTION MOULDING PROCESS

Injection moulding is a manufacturing process whereby plastic is melted and injected into a closed mould. Once the product cools and hardens it is ejected from the mould.

Injection moulded products include:

• Yogurt and cream cheese tubs

• Food tubs and lids

• Infant formula spoons, scoops and lids

• Lids with utensils

• PET preforms

• Caps & closures - for food and non food products