TRUSTED AND EASY TO OPEN PACKAGING

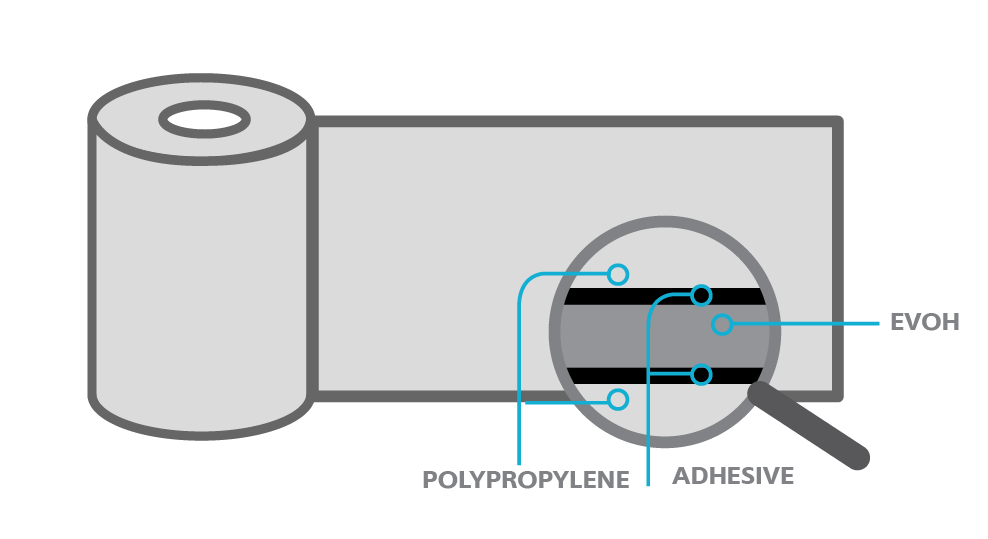

Multilayer sheet packaging is used extensively in the food industry because it’s ideal for food products. It’s convenient for consumers and can be configured to suit differing refrigeration requirements and shelf-life.

The multilayering technology and design is adaptable and cost-effective, allowing for a multitude of layer configurations and material blends. Packs meet all food safety regulations and are lightweight, recyclable and premium quality.

EXTRUDED MULTILAYERED SHEET OPTIONS

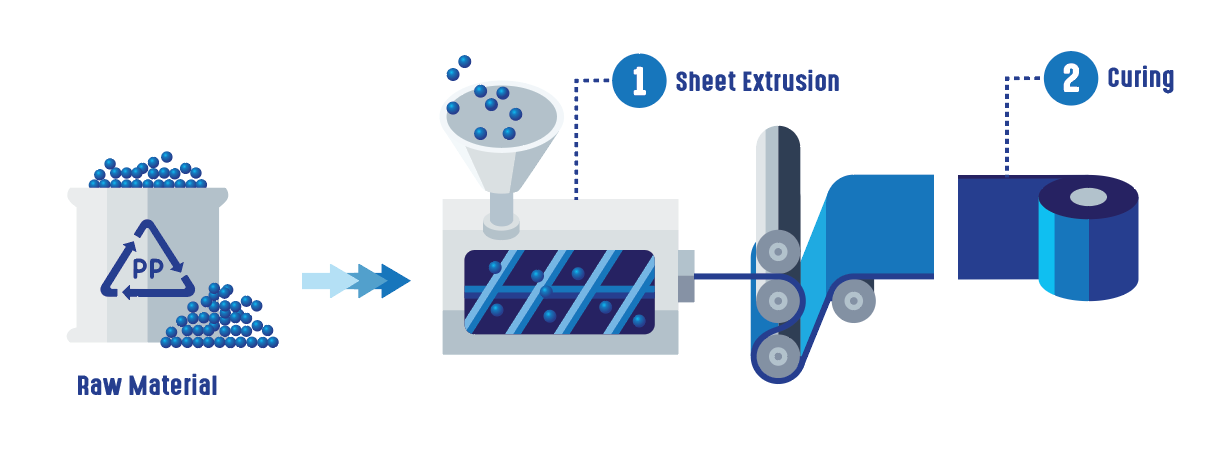

Extrusion and layering technology allows for a multitude of layer configurations and material blends. Vexcel Pack’s sheet is suitable for all in-house thermoforming applications, and the roll format ensures logistics costs are kept to a minimum.

OUR PLASTIC PACKAGING OPTIONS PROVIDE:

• High capacity, lowcost packaging

• Technology capability of up to 13 layers for additional structure, stability and visibility

• Consistently high quality materials

A high volume plastics manufacturing process

Multi-layer sheet extrusion is a high volume plastics manufacturing process that involves mono or multi-layer co-extrusion of up to 13 layers of plastic. Co-extrusion is the application of one or more layers on top of a base material with the objective of adding properties such as UV-absorption, texture, energy reflection, oxygen and gas barrier, etc.

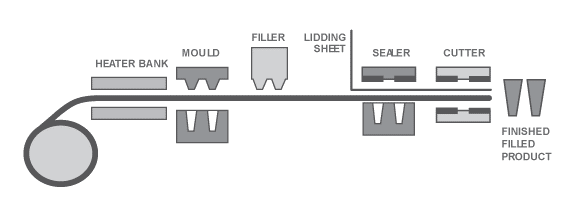

Multi-layer sheet extrusion involves thermoforming whereby plastic sheet is heated until soft, and formed via a mould into a new shape. Common materials include PET, high-density polyethylene, polystyrene and ABS (Acrylonitrile Butadiene Styrene).

Sheet is differentiated from film by its thickness - with sheets over 0.25mm thick being considered a sheet. Thinner plastic sheets are generally thermoformed into plastic trays, clam shells, bowls or cups.

Vexcel Pack also offers industry leading, contamination free ‘form fill seal’ packaging solutions, including horizontal form fill seal (HFFS) or vertical form fill seal (VFFS) processes.