PACKAGING THAT’S EASY TO STOCK AND SHOP

Plastic containers offer lightweight, shatterproof, coloured and transparent packaging solutions for shelf stable food. Popular with consumers, plastic can help them quickly identify brand, product type and variant on the shelf.

Barrier containers are ideal for food sterilisation, pasteurisation or aseptic filling. The high oxygen, water and aroma barrier make the product shelf stable, so this type of plastic is suitable for preservative free contents that do not require refrigerating.

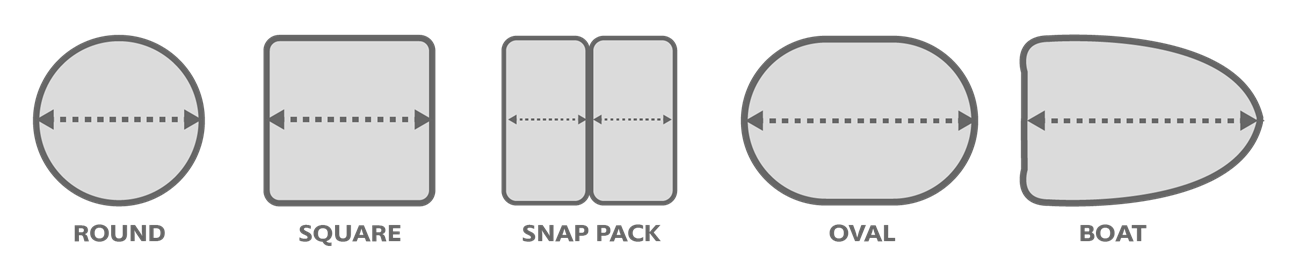

We can design and customise packs that protect the contents and help

your brand stand out. Plastic packaging can be used for many products including fruit and vegetables, soups, ready meals, rice, coffee, pet food, dairy and beverages.

OUR PLASTIC PACKAGING OPTIONS PROVIDE

• Improved quality for products that spend time in storage and on the shelf

• Vibrant colour range for stronger branding, recognition and shelf appeal

• UV protective transparent packaging that keeps products looking good

• Greater stand-out and differentiation through custom design and materials

Effective and affordable standard designs to help you get new concepts and products to market quickly and confidently

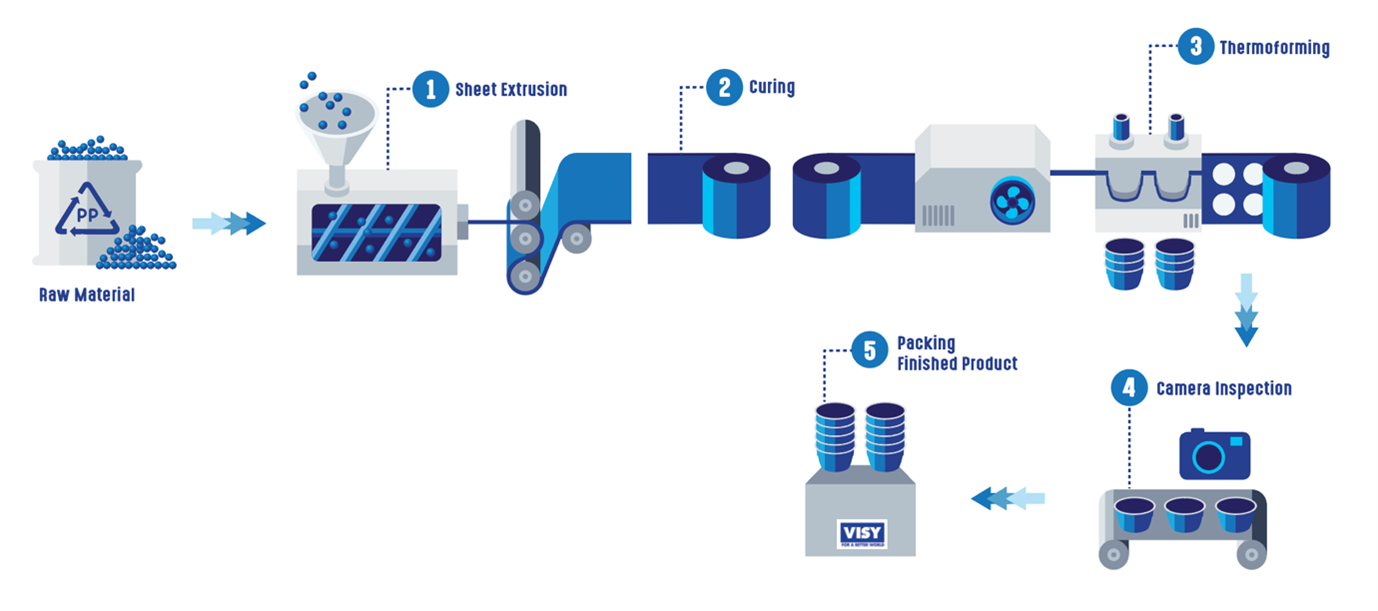

Vexcel Pack has extensive experience and expertise in providing precision,

scalable thermoforming services and products

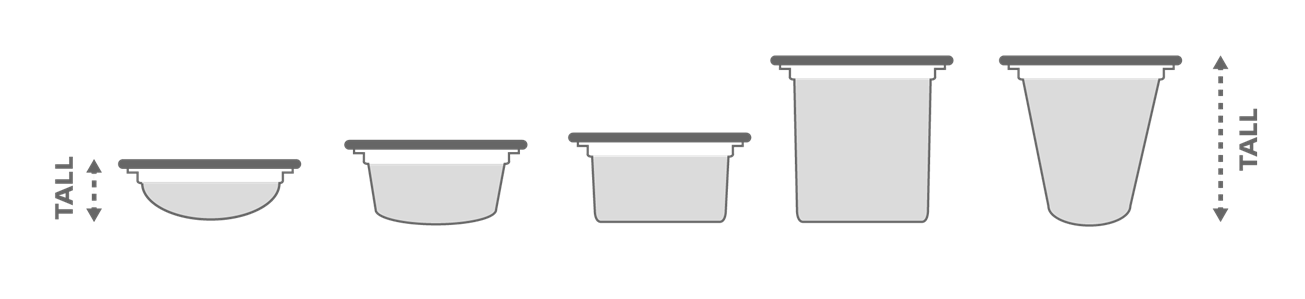

Thermoforming is a process where plastic sheeting is formed into cup, tray or lid shapes using a combination of heat, a pre forming plug and air pressure. Barrier or non-barrier sheet material can be used.

Thermoformed products include:

• Barrier sheet - cups, trays and overcaps

• Non-barrier sheet - cups, trays and overcaps

Tilt machines with cut-in-place tooling can produce parts with higher dimensional accuracy than traditional form-cut-stack tooling. Tooling price is higher but can yield very high output (>1M per day).

Inline camera inspection is available on most products, depending on their design.